“If, in the laboratory, we were to take natural elements and combine them into a perfect aggregate, we probably would end up with perlite.” That from Dr. Harry Huntzicker, one-time director of research for US Gypsum Corp., as quoted in an article about perlite that ran in the December 1954 issue of Popular Mechanics magazine.

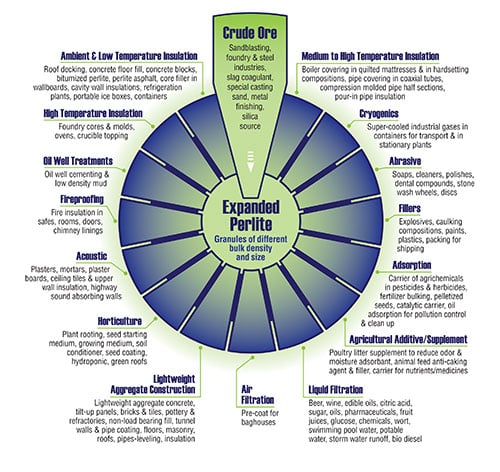

Perlite is marketed to industry in two forms—crude ore and as expanded particles in various size grades and even form factors—expanded particles (clusters of bubbles), crushed and milled expanded perlite, even individual bubbles/microspheres (using a sophisticated manufacturing technique).

A Versatile Mineral

Expanded perlite exhibits very low thermal conductivity, low sound transmission, high fire resistance, a large surface area and controllable moisture retention and drainage. It is chemically inert, sterile, non-toxic and non-fibrous, free of organic impurities, and has a neutral pH. Regarded as an essentially “environmentally safe” building material, perlite is incredibly versatile and is used in a wide range of products and processes in industry—as a soil amendment, as insulation, as a filter aid, as lightweight concrete aggregate, liquid waste stabilizer, and many more. Learn more about the specific uses and applications of perlite by clicking on the proceeding link and viewing the linked documents immediately below.

The Expansion Process

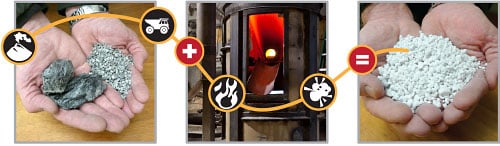

Perlite ore is a glassy volcanic rock with a vitreous, pearly luster and a characteristic concentric or perlitic fracture. Closely related to pumice, it differs from other volcanic glasses principally in its combined water content, which produces the unusual characteristic of “popping”—expanding up to 20 times its original volume when exposed to rapid, controlled heating. Rapidly heating perlite ore to temperatures of about 900°C (1,700°F) softens the volcanic glass, causing entrapped water molecules in the rock to turn to steam and expand the particles like popcorn. The resulting expanded particles—actually clusters of minute glass bubbles—are spherical in shape, usually fluffy or frothy, highly porous due to a foam-like cellular internal structure, and have a very low density.

The expansion process also creates one of perlite’s most distinguishing characteristics: its white color. While the crude rock (ore) may range from transparent light gray to glossy black, the color of expanded perlite ranges from snowy white to grayish white.

Perlite is a form of natural volcanic glass, and is classified as chemically inert, with a pH of approximately 7. Expanded perlite can be manufactured to weigh as little as 2 pounds per cubic foot (32 kg/m3) making it adaptable for numerous applications.

HISTORICAL ORIGIN. As is often the case, the fact that crushed perlite expands under high heat was discovered by accident. In 1939, Lee Boyer operated an assay office in Superior, Arizona. He’d been working for months to fuse a mixture of silicates with hopes of developing a new insulating material for the telephone industry. And then came the day he threw a shovelful of crumbled perlite into the open-end firebox of an old converted assay furnace. The popping that followed was a surprise, as was the end result—frothy mineral nuggets with a bubbly cellular structure of sealed pores. Perfect to resist heat conduction! With further help from the Arizona Department of Mineral Resources, he discovered why—perlite contains a small percentage of trapped water in the raw ore. They also worked to quantify the insulative, fire-proof and lightweight character of expanded perlite. A small pilot plant provided Boyer with enough expanded perlite to began exploring applications. One of the first: using the white, lightweight perlite in place of sand for a plaster used to refinish the screen of a Phoenix-area drive-in theatre1.

Capacity for Liquid Retention

Expanded perlite is uniquely structured to hold water (and other liquids) with three factors contributing to total capacity: 1) water his held on the frothy surface of a perlite particle, 2) it is held in the voids and channels inherent in physical structure of the individual particles, and 3) it is held between the particles. The last factor—the inter-particle framework holding capacity—is directly related to particle grade and provides great flexibility to industry. Capacity is increased with fine grades, as more densely packed particles provide more surface area and more inter-particle pore spaces to hold water. Larger grades hold less and drain more quickly. The application determines grade selection and moisture retention and release needs.

Physical Characteristics

The Perlite Institute, a global association of commercial perlite mining and expansion companies, published a fact sheet that provides a typical physical properties breakdown and a typical chemical/elemental analysis of perlite. Download the PDF below.

Health Effects

The perlite industry has been at the forefront of testing and understanding any health effects that may be associated with perlite and perlite products. Much of the industry research effort is sponsored by the Perlite Institute, an international trade association organized in 1949 by perlite mining and processing companies. The following is from a Perlite Institute publication:

“Perlite has been the subject of numerous health studies conducted by scientific and governmental research organizations. Significantly, no test result or information indicates that perlite poses any health risk. Indeed, the uniform result of all health studies points forcefully to the conclusion that perlite and perlite products are safe for consumer use.

“Worker health studies provide direct support for the conclusion that perlite is a safe product. For example, studies by Cooper (1975; 1976), Cooper and Sargent (1986), and Weill (1990; 1994) indicate that perlite poses no significant respiratory health risk to workers. As with all workplace dusts, perlite can function as a nuisance dust, so exposure limits are set at those levels. For some workers, exposure can result in temporary physical irritation, discomfort, impaired visibility, and enhancement of accident potential. However, a health study (1994) of perlite by Dr. Hans Weill of Tulane University concluded that workers exposed to perlite are free of any measurable adverse respiratory effects.”

A Low Impact, Sustainable Resource

The global perlite industry actively mines a total of less than 8 square km (3 sq miles)—about 1% of the total perlite deposits available worldwide. Perlite mining has limited environmental impact. There is little overburden to manage, minimal waste, and no chemicals are needed to process the ore. Once mined, perlite does not create by-products during expanding and processing, as only the physical form is altered.

About Hess Perlite

Hess Perlite began mining and expansion operations back in 1965 doing business as Idaho Minerals. Expansion was initially done in a small facility next to the mine. A larger facility was later built in nearby Malad City where they had access to a rail spur. The perlite expansion facilities were later relocated to the Malad Industrial Park and upgraded for increased production capacity and improved efficiencies.

Hess Perlite is both a perlite mining and expanding operation: we sell graded crude ore for industry applications (ie. slag coagulant) and ship ore by rail to other perlite expanders. We also operate an expansion facility, producing various grades of expanded perlite that is available in palleted bags (4 cu/ft) and supersacks (55 cu/ft and 118 cu/ft).

Production Capacity. Hess Perlite has the capacity to expand 10,000 cubic feet of perlite per 24-hour period—the equivalent of 2500 4-cubic-foot bags or 85 tall supersacks. Although the perlite mine has been in operation since 1965, there are still over 10 million tons of perlite reserves remaining, all on patented ground.

Location. The offices of Hess Perlite are located in the Malad Industrial Park just south of Malad City, Idaho, which is 13 miles north of the Utah state line on Interstate 15. Use I-15 Exit #13. Turn west from the exit, then continue west until you come to a stop sign at a T-Intersection. Turn Left (South) and drive for 1 mile. Drive until you see a sign on your right that says “Malad Industrial Park - Hess Pumice Products.” Turn right at that sign. Hess Pumice is located in same park, and the Perlite and Pumice operations share the same corporate offices. The perlite facilities—production, quality control labs, warehouses, and loading docks—are located to the right as you enter the park.

Mapping Software Warning. Our address (100 Hess Drive, Malad City, Idaho) does NOT show up correctly in some mapping and direction-finding software. In fact, it places you well off-course—on the other side of the county. You can enter the address of 1000 S. Main, Malad City, ID—that will put you at the entrance of the Industrial Park. Or use these coordinates: 42.1686 LAT, -112.241 LONG.

Sales, Information, and Logistical Expertise. To talk expanded perlite grades or raw ore, logistics, costs, availability and production schedules, contact Jason Kimberling, Sales Manager, at (208) 766-4777 x142 or email info@hessperlite.com

As for the shipping—we’re very good at getting your perlite to you efficiently and economically. We’ve been shipping our expanded perlite regionally, our perlite ore nationally, and pumice worldwide for decades. Our dedicated logistics manager can help arrange shipping, secure the best rates, and manage the process from load-out to arrival.

[1] That Wonderful Volcanic Popcorn, by Charles Ballenger and Richard Dunlop, Popular Mechanics, December 1954